Introduction

A pressure gauge is one of the simplest yet most important instruments in any industrial system. Whether it’s in oil and gas, chemical processing, HVAC, water treatment, or manufacturing, accurate pressure readings ensure efficiency, safety, and smooth operation.

However, like all mechanical devices, gauges degrade over time. If a pressure gauge fails without warning, it can lead to costly downtime, equipment damage, or even safety hazards. Recognizing early warning signs can help you replace your gauge before failure occurs.

Here are the 10 key signs your pressure gauge needs replacement.

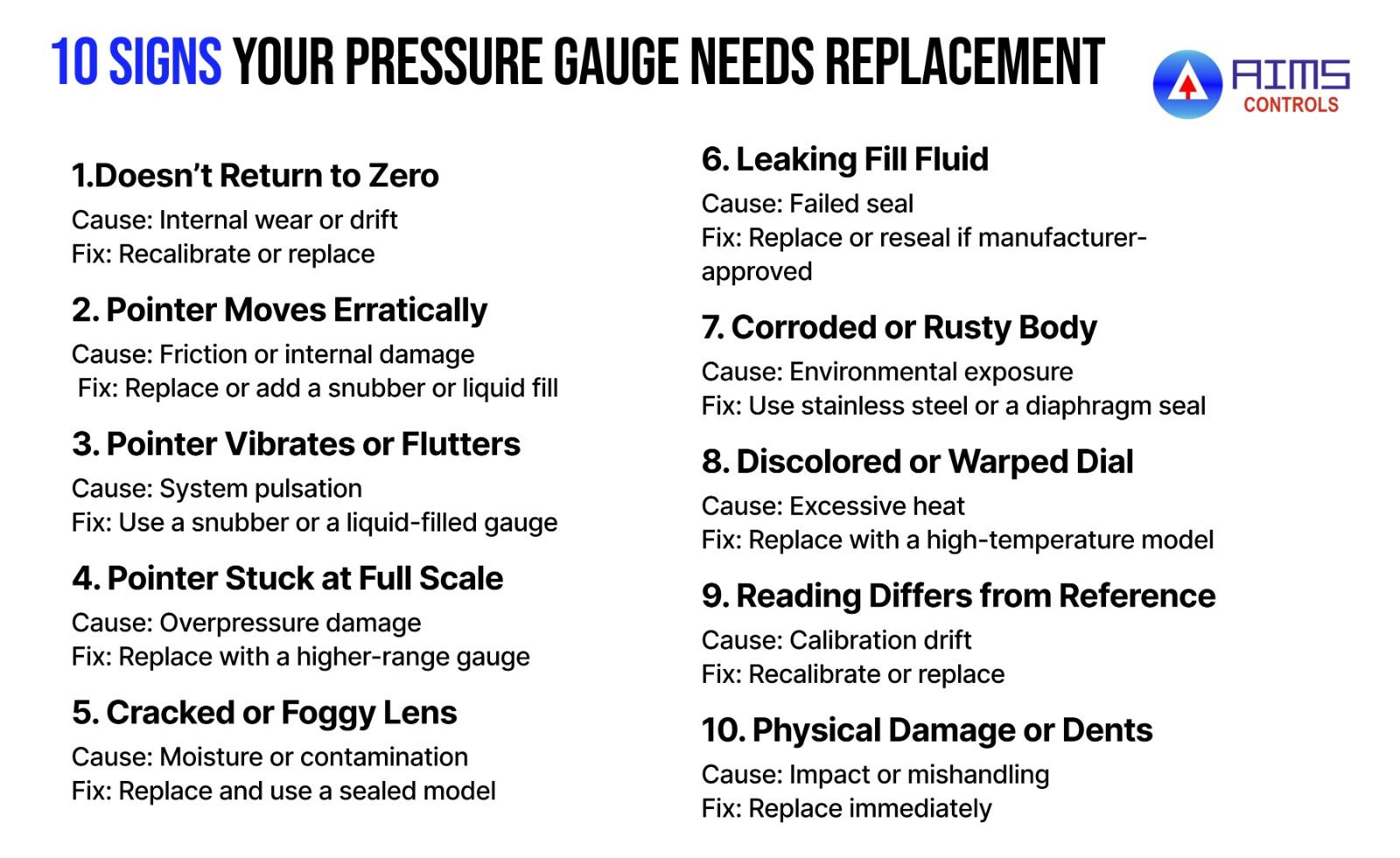

1. Pointer Doesn’t Return to Zero

When the system is depressurized, the gauge pointer should rest exactly on zero. If it doesn’t, internal wear or deformation has occurred.

Why it matters: This indicates calibration drift or mechanical damage.

Action: Replace or recalibrate the gauge immediately.

2. Pointer Moves Erratically or Sticks

A sticky, jumpy, or hesitant pointer is a sign of friction, dirt, or internal damage.

Why it matters: Delayed or frozen readings can lead to incorrect system decisions.

Action: Replace the gauge or install vibration-dampening accessories like snubbers or liquid filling.

3. Pointer Vibrates or Flutters

Constant pointer vibration means excessive system pulsation or mechanical resonance.

Why it matters: Continuous fluttering shortens gauge life and causes inaccurate readings.

Action: Replace the gauge and install a pulsation snubber or a liquid-filled model.

4. Pointer Pegged at Full Scale

If the pointer is stuck at maximum pressure or against a stop pin, the gauge likely suffered overpressure.

Why it matters: Overpressure permanently deforms the sensing element (Bourdon tube).

Action: Replace immediately and use a gauge with a higher pressure range.

5. Cracked or Foggy Lens

A fogged, cracked, or scratched gauge lens allows moisture, dust, or chemicals to enter the housing.

Why it matters: Contamination can corrode internal parts, leading to inaccurate readings.

Action: Replace the gauge and ensure future installations use properly sealed models.

6. Leaking or Evaporated Fill Fluid

For liquid-filled gauges, loss of glycerin or silicone fill indicates a failed seal.

Why it matters: Without fill, vibration resistance is lost, accelerating internal wear.

Action: Replace the gauge or reseal only if manufacturer-approved kits are available.

7. Corrosion or Rust on the Gauge Body

Visible rust, corrosion, or pitting on the case or connection threads is a clear red flag.

Why it matters: Corrosion weakens the gauge structure and contaminates readings.

Action: Replace with a corrosion-resistant stainless-steel gauge and consider diaphragm seals.

8. Discolored or Warped Dial Face

If the gauge face is faded, burnt, or melted, it’s been exposed to extreme temperatures.

Why it matters: Heat distortion affects readability and may warp internal components.

Action: Replace the gauge with one rated for the proper temperature range.

9. Gauge Reads Differently from Reference Instrument

When compared to a calibrated reference, if your gauge shows a consistent deviation, it’s no longer accurate.

Why it matters: Drift beyond ±2% of full scale can compromise process control and safety.

Action: Replace or recalibrate the gauge as part of regular maintenance.

10. Visible Physical Damage or Dents

Any dent, crack, or bent fitting can affect gauge integrity.

Why it matters: Physical impact may have damaged internal linkages or the Bourdon tube.

Action: Replace immediately—damaged gauges cannot be trusted.

Why Early Replacement Matters

Pressure gauges are small instruments, but they play a critical role in keeping entire systems safe and efficient. Waiting for one to fail can lead to consequences far greater than the cost of replacement. Here’s why timely replacement makes a significant difference:

1. Safety

A faulty gauge doesn’t just give wrong readings—it can hide dangerous pressure build-ups or drops within your system. This can result in overpressure events, leaks, or even equipment rupture. In environments involving steam, gas, or hazardous fluids, a misreading can put operators and assets at serious risk. Early replacement ensures accurate pressure monitoring, preventing accidents before they happen.

2. Reliability

When a gauge starts failing, it often affects the entire operation. Inconsistent or fluctuating readings can cause false alarms, unnecessary shutdowns, or delayed responses to real issues. By replacing worn or inaccurate gauges early, you maintain a stable system that operates as expected—minimizing downtime and unplanned maintenance interruptions.

3. Accuracy

Precision is vital in industries where compliance and performance depend on correct pressure levels—such as pharmaceuticals, food processing, oil & gas, and HVAC. Even slight deviations can lead to inefficient energy use, product inconsistency, or quality control failures. Replacing aging gauges ensures that your system stays within calibration tolerance and delivers the accurate data your processes rely on.

4. Cost Efficiency

Replacing a pressure gauge at the right time costs far less than dealing with equipment damage, production loss, or safety incidents. A single failed gauge can cause a cascade of costly consequences—from damaged pumps and valves to unscheduled downtime. Proactive replacement is a small investment with a high return, protecting both operational uptime and financial performance.

Preventive Tips to Extend Gauge Life

Even the most durable pressure gauges require proper handling and maintenance to deliver accurate, long-lasting performance. With a few smart preventive practices, you can significantly extend the lifespan of your gauges and reduce replacement frequency.

1. Select the Right Gauge Range

Choosing the correct pressure range is the foundation of gauge longevity. A general rule is to select a gauge where the normal operating pressure falls between 25% and 75% of the full-scale range. This ensures the gauge is not consistently operating at its limits, which can fatigue the Bourdon tube and distort readings over time.

If your system experiences frequent pressure surges or spikes, select a gauge with a higher range or add overpressure protection. This small adjustment can prevent premature mechanical wear and maintain long-term accuracy.

2. Use Snubbers and Dampeners

Vibration and pressure pulsation are among the top causes of gauge failure. Installing snubbers, restrictors, or liquid-filled gauges helps absorb sudden pressure fluctuations, protecting the internal mechanism from constant stress.

In environments with heavy machinery or fluid pulsation, these accessories are essential—not optional. They stabilize the pointer movement, improve readability, and significantly increase the gauge’s operational life.

3. Conduct Regular Inspections

Routine visual inspections are the simplest yet most effective way to detect early signs of gauge wear. Check for:

- Cracked or fogged lenses

- Bent or sticky pointers

- Zero offset when the system is depressurized

- Corrosion or leaks around the fitting

Detecting these issues early prevents inaccurate readings or complete gauge failure during operation. For critical systems, incorporate these checks into your preventive maintenance schedule at least once a month.

4. Follow a Scheduled Calibration Program

Even high-quality gauges drift over time due to mechanical fatigue and environmental conditions. Verifying readings against a calibrated reference gauge every 6–12 months ensures continued accuracy and compliance with process standards.

If your gauge fails to meet calibration tolerance, replacement is often more cost-effective than repair. Keeping a documented calibration history also supports audits and quality certifications in industries like manufacturing, energy, and food processing.

5. Ensure Proper Environmental Protection

The environment where your gauge operates has a direct impact on its durability. For corrosive, high-moisture, or high-temperature conditions, choose stainless-steel or liquid-filled gauges designed to resist oxidation, vibration, and condensation.

In extreme environments, consider remote mounting, cooling adapters, or diaphragm seals to isolate the gauge from direct exposure to aggressive media or high temperatures. This extra layer of protection drastically extends service life and reliability.

In Summary

By applying these preventive measures—correct gauge selection, pulsation control, regular inspection, scheduled calibration, and environmental protection—you not only extend the lifespan of your pressure gauges but also improve system safety, reliability, and performance. Preventive care costs little compared to the expense of unscheduled downtime or damaged equipment.

When to Replace vs. Calibrate

| Condition | Recommendation |

| Minor zero drift | Calibrate |

| Damaged pointer or face | Replace |

| Internal corrosion or fill loss | Replace |

| Consistent pressure drift | Replace |

| After an overpressure event | Replace |

Conclusion

A failing pressure gauge is not just an inconvenience—it’s a risk. Regular inspection and proactive replacement protect your systems from costly damage and unsafe conditions.

At Aims Controls, we offer a full range of industrial-grade pressure gauges designed for reliability, durability, and precision across industries.

Explore our collection or speak to our experts to find the right gauge for your application.