A glycerin-filled (liquid-filled) pressure gauge damps vibration and pulsation, keeping the pointer steady and extending movement life. It’s the default choice for a pump skid pressure gauge with discharge ripple.

Choose a dry gauge + pulsation snubber when temperatures are high, media/cleanliness rules don’t allow fills, or you need maximum visibility. See the decision table and installation checklist below to eliminate needle flutter at the source.

Need a fast recommendation? Request a Gauge Spec or Request for Quotation.

What causes “needle flutter” on pump skids?

Vibration & pulsation 101. Most pump skid pressure gauge problems start with energy coming off the pump.

- Discharge ripple: Centrifugal pumps create mild, cyclical pressure variation; positive-displacement (PD) pumps create sharper pulses that hit the gauge movement like taps on a spring.

- Pipework vibration: Unbraced piping, misalignment, or nearby rotating equipment transmits mechanical vibration straight into the gauge.

- Cavitation/air entrainment: Vapor bubbles forming and collapsing—or pockets of air—add rapid pressure spikes that make the gauge needle flutter worse.

Why Flutter is bad

A bouncing pointer is hard to read accurately, invites operator error, speeds up wear of pivots/gearing, and can lead to early gauge failure. On noisy skids, a “dancing” pointer also hides real problems (blocked strainers, failing check valves) until they turn into downtime.

Root-cause mindset. First, reduce pulsation and vibration at the source where possible; then select the right gauge and damping accessories. Good practice is: fix the ripple → isolate the gauge from vibration → add controlled damping.

Call-out: Flutter = pointer oscillation faster than the operator can confidently read.

How liquid filling actually stops flutter

Mechanism (why it works)

In a liquid-filled pressure gauge, the case is partially filled with a viscous fluid that surrounds the movement (gears, links, pointer arbor). When pulsation or vibration tries to whip the pointer, the fluid resists rapid motion—like a tiny shock absorber—so gauge needle flutter is damped. The bourdon tube still senses pressure normally; the fill fluid doesn’t touch the process. It simply slows the pointer’s oscillation and cushions shock.

Common fill fluids (when to use which).

- Glycerin: cost-effective, general-purpose; ideal for most pump skid pressure gauge applications with moderate ripple.

- Silicone (silicone-filled gauge): stays stable in cold and handles higher vibration; better choice below ~-10 °C or where severe pulsation exists.

Pros you’ll notice.

- Steady, readable pointer—even on PD-pump ripple.

- Longer movement life; fewer failed gauges and callouts.

- Less fogging/condensation inside the case when properly sealed.

- Helps operators spot real issues (cavitation, blockages) instead of chasing bounce.

Cons and caveats.

- Temperature limits: glycerin thickens in cold; any fill expands with heat (use vented plug, or choose silicone/remote mount).

- Visibility: fluid can yellow or “mist” over time in harsh sun.

- Service constraints: for oxygen, sanitary, paint, or ultra-clean service, prefer dry plus pulsation snubber/pulsation dampener, or isolate with a diaphragm seal/gauge siphon as the application demands.

- Accuracy: the fill doesn’t change calibration; just open the case breather (if fitted) after installation to avoid zero shift.

This is the physics behind the advantage in glycerin-filled vs dry pressure gauge choices: liquid filling tames pointer motion; accessories and mounting handle the extremes.

Glycerin-filled vs Dry Gauges

| Situation | Best pick | Why | Accessory to add |

| Moderate vibration/pulsation on the pump skid | Glycerin-filled (liquid-filled) pressure gauge | Damping steadies the pointer and protects the movement | — |

| Heavy pulsation (PD pump, water hammer) | Dry + snubber or filled + snubber | Orifice/porous snubber tames pressure shocks | Pulsation snubber/pulsation dampener |

| Low ambient (< −10 °C) | Silicone-filled or dry + remote mount | Glycerin thickens in cold; silicone stays fluid | Capillary/remote mount |

| High ambient or hot process | Dry or seal + capillary | Fill can expand; keep movement cool and stable | Diaphragm seal, gauge siphon (steam) |

| Corrosive/viscous/crystallizing media | Gauge on the diaphragm seal (isolates fill) | Protects the bourdon tube from the media | Seal + correct fill-fluid selection |

| Hygiene/oxygen / paint-critical service | Dry (or approved special fill) | Avoid contamination/misting; keep visibility high | Dry gauge + snubber for damping |

When to choose a glycerin-filled gauge

Use a liquid-filled pressure gauge when:

- The pointer is bouncing from vibration/pulsation on a pump skid (PD pumps, close-coupled mounts, or unbraced pipe).

- Operators need a steady, readable value to avoid errors and trips.

- Gauges fail early from wear on pivots/gearing—classic gauge needle flutter damage.

Benefits you’ll see:

- A steady pointer that’s easier to read and log.

- Longer movement life and fewer replacements.

- Better visibility into real issues (e.g., cavitation or blockages) instead of chasing bounce.

Spec notes (get it right first time):

- Case size: 63–100 mm (2.5″–4″) is typical on skids.

- Materials: stainless case and bourdon tube for harsh environments.

- Accuracy class: pick per need (e.g., ASME B40.100 or EN 837-1).

- Range: center normal operating pressure in the middle third of the dial.

- Fill choice: glycerin-filled pressure gauge for general purpose; silicone-filled gauge for colder ambient or harsher vibration.

- Add a pulsation snubber if the ripple is severe.

Browse options: See our Pressure Gauges lineup to match range, connection, and fill type: Pressure Gauges.

When Not to Choose Glycerin (and What to Do Instead)

Very hot service/steam.

Skip fills that can expand with heat. Use a dry pressure gauge with a gauge siphon to cool the process before it reaches the movement, or isolate the instrument with a diaphragm seal + capillary/remote mount so the movement sits away from the heat source.

Recommended: Gauge Siphon • Diaphragm Seal • Capillary / Remote Mount

Very cold ambient (< −10 °C).

Glycerin thickens in the cold and can slow the pointer. Choose a silicone-filled gauge for low temperatures, or use a seal + capillary to relocate the gauge to a milder area.

Recommended: Diaphragm Seal

Media/cleanliness constraints (oxygen, sanitary, paint-critical).

Avoid potential contamination or case “misting.” Stay dry and add inlet damping, or isolate the process with a diaphragm seal matched to the media.

Recommended: Diaphragm Seal • Pulsation Dampener / Snubber

Severe ripple, but maximum clarity is needed.

If sunlight or aging makes a liquid-filled pressure gauge harder to read, keep it dry and control pulses with a pulsation snubber/pulsation dampener. You’ll tame needle flutter without adding fill fluid.

Recommended: Pulsation Dampener / Snubber

Accessories That Actually Kill Flutter (and Extend Gauge Life)

Pulsation snubber.

A porous element or adjustable orifice at the gauge inlet that smooths pressure waves before they reach the movement. It’s the first-line fix for needle flutter on pump skids and pairs well with both dry and glycerin-filled pressure gauges. Install close to the tap for best results.

Recommended: Pulsation Dampener / Snubber

Restrictor (throttle) screw.

A tiny, built-in restrictor that adds damping right at the gauge port. Low cost, easy to retrofit, and ideal for moderate ripple when you want to keep a dry gauge clear and highly visible.

Pulsation dampener/needle valve.

Gives you “tunable” damping—close the needle slightly until the pointer steadies without lagging. Use alongside a liquid-filled pressure gauge for severe pulsation (PD pumps, water hammer).

Gauge saver / over-pressure protector.

Spring-loaded or gas-charged devices that shield the movement from spikes and accidental isolation. They don’t stop fluttering by themselves, but they prevent damage while you dial in damping.

Isolation valve (for changeout).

A small block valve beneath the gauge lets you isolate, swap, or service without shutting down the skid—critical for keeping instruments healthy over time.

Bundle it right: Request a Gauge Spec and we’ll size a gauge + pulsation snubber combo for your pump type, range, and temperature.

Sizing & Selection Checklist (1-Minute Scan)

- Pressure range: Put normal operating pressure in the middle third of the dial to minimize wear and maximize readability.

- Accuracy class: Choose per need (e.g., ASME B40.100 Class 1.6/1.0 or EN 837-1 1.6/1.0/0.6). Higher accuracy for set-point critical skids.

- Case & wetted materials: Stainless steel case; bourdon tube material compatible with media (consider diaphragm isolation for corrosives).

- Dial size & visibility: 63–100 mm (2.5″–4″) are common on skids; size up if the gauge sits farther from the operator or behind guarding.

- Connection & mount: ¼″ or ½″ NPT/BSP, bottom or back mount; plan for panel kits if needed.

- Damping choice:

- Glycerin-filled pressure gauge for general vibration/pulsation.

- Silicone-filled gauge for cold ambient or harsher ripple.

- Dry + pulsation snubber/pulsation dampener when temperatures are high or cleanliness/visibility is critical.

- Process conditions: Note temperature, vibration, cavitation/air entrainment, and duty cycle; add protection if spikes are likely.

- Isolation & protection: Consider a diaphragm seal (for viscous/corrosive media) and a gauge siphon for steam/hot service.

- Environment: Sun/UV, washdown, IP/ingress needs, hazardous area (ATEX/FLP).

- Commissioning & docs: Open the case breather (if fitted) after installation to avoid zero shift; specify calibration certificates and material test reports if required.

Installation on a Pump Skid — Do It Once, Read It Forever

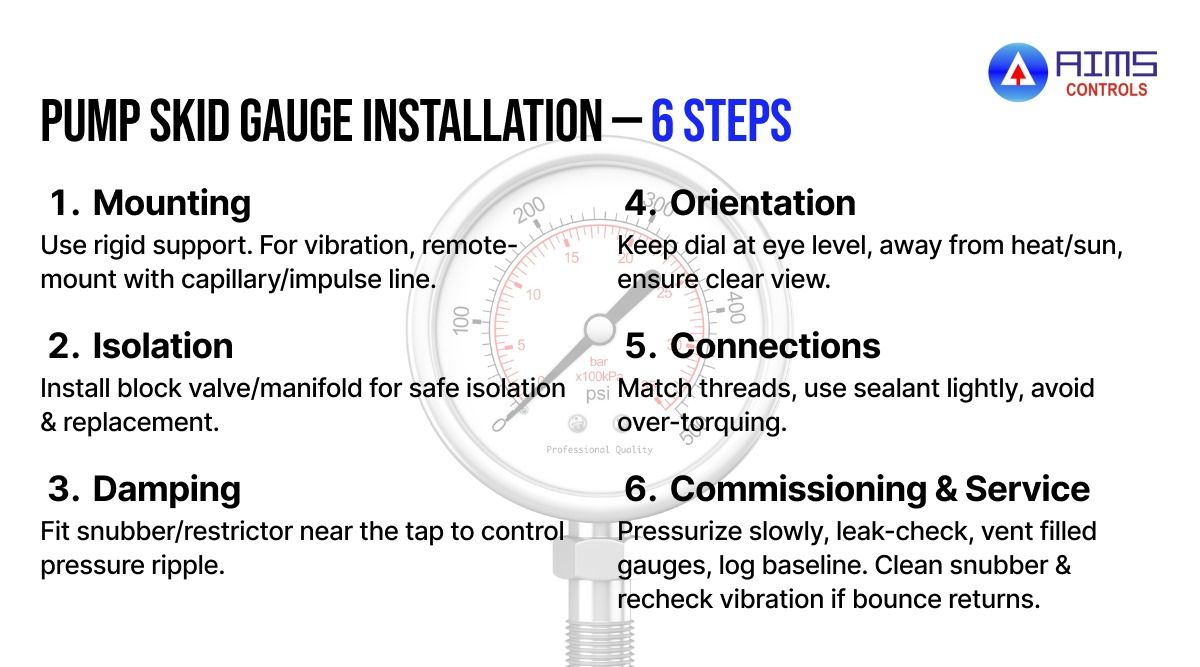

Mounting

Install the gauge on a rigid support, not on a vibrating span of pipe. If the pump or pipe vibrates heavily, remote-mount the gauge on a stand and connect via a short capillary or impulse line.

Isolation

Always include a small block valve or a valve manifold beneath the gauge so you can isolate, vent, and swap the instrument safely without shutting down the skid.

Browse: Valves • Manifolds

Damping at the tap

Fit a pulsation snubber/restrictor as close to the pressure tap as possible—before elbows and long runs—to tame ripple right where it starts.

Orientation & visibility

Face the dial toward the operator at standing eye level. Keep it clear of hot surfaces and insulate or shield from sun/UV if the skid is outdoors.

Connections

Match thread (¼″ or ½″ NPT/BSP), use thread sealant sparingly, and avoid over-torquing, which can distort the case or bourdon connection.

Commissioning

Pressurize slowly on first startup, check for leaks, and—on filled gauges—open the case breather/vent plug (if provided) to prevent zero shift. Snap a baseline photo of the reading for your log.

Service tips

If the pointer bounce returns, verify the snubber cleanliness, look for new vibration sources (unbraced pipe, misalignment), and confirm the gauge range still places normal pressure in the middle third of the dial.

FAQ — Short, Factual Answers

Do liquid-filled gauges read lower or higher?

Neither. The fill fluid only damps motion; it doesn’t change calibration. Open the case breather (if fitted) after install to avoid zero shift.

Can I refill or change the fill fluid?

Yes—on serviceable models. Use the correct viscosity (glycerin or silicone), fill to the mark, and reseal to prevent fogging.

Why does my filled gauge look cloudy?

UV exposure, moisture ingress, or aged fluid. Choose proper window material, keep the vent closed after equalizing, and replace fluid if needed.

Will a snubber fix all needle flutter?

A pulsation snubber/pulsation dampener cuts pulsation dramatically, but heavy vibration may still need a glycerin-filled pressure gauge (or remote mount) for best results.

When do I need a diaphragm seal?

For corrosive, viscous, crystallizing, or sanitary media—and for high temperature. A seal protects the bourdon tube and extends gauge life.

Which standard should I follow?

Match accuracy and construction to ASME B40.100 or EN 837-1 as your plant requires.

Need certificates or baseline readings? Book Calibration and we’ll include documentation with your shipment.

Get the Spec Right the First Time

Send AIMS Controls your process details—media, temperature, normal/max pressure, pump type, vibration level, connection & mount, and whether you prefer glycerin filled vs dry pressure gauge. Our team will size the range, pick the right fill (glycerin or silicone), and add the correct pulsation snubber / pulsation dampener, diaphragm seal, or gauge siphon where needed.

Where we are

AIMS Controls, Plot No. 165, Vibrant Business Park, NH 48, GIDC, Vapi – 396195, Gujarat, India.

Where we serve

We support industrial clients across Gujarat and pan-India, with shipping and on-call application support to major process and manufacturing hubs.

- Request a Gauge Spec: we’ll return a fit-for-purpose recommendation for your pump skid.

- Send RFQ: include quantity, delivery location, and required documents for pricing and lead time.

- Ask an Applications Engineer: get a quick review of your layout and damping options.Book Calibration: add certificates and documentation to your order via our Calibration & Documentation Services.

Prefer to self-select first? Browse Pressure Gauges, pair with Snubbers / Dampeners, add Diaphragm Seals & Capillaries, and finish with Valves & Manifolds for safe isolation.